Fluid Drive Coupling

Ever-power Transmission Co., Ltd. specializes in manufacturing various mechanical transmissions and hydraulic transmissions.

PRODUCT

OUR PRODUCT

T fluid drive coupling

The type T fluid drive coupling is the basic version of a constant-filled collar. Such couplings are used in drives for different applications such as cranes, bucket conveyors, stackers, and reclaimers. These couplings are particularly suitable if overload protection and vibration damping are required. Your drive equipment is then protected with the added benefit of increasing system productivity. This fluid drive coupling is also available with two work circuits (type DT). The parallel acting courses double the power transmission.

TVS fluid drive coupling

The type TVS fluid drive coupling is comparable to the fluid coupling type TV; however, enhanced with an annular chamber. This results in more operating fluid in the coupling. High thermal capacity facilitates higher starting frequencies and reverses operations, protects the drive against overload, and dampens its torsional vibrations. This protects your system and increases its productivity. The type TVS fluid drive coupling is used primarily in crusher drives.

TDM-SAE constant-fill fluid drive coupling

The type TDM-SAE constant-fill fluid drive coupling is used in diesel engine drives for mobile shredding machines. The coupling is suitable for accelerating moderate masses. Thanks to the hydrodynamic principle, the fluid drive coupling dampens torsional vibration and protects the drive components against overload, which increases the productivity of your system.

fill-controlled fluid drive coupling

The fill-controlled fluid drive coupling, type DTPKWL2, is especially suited for heavy-duty usage in armored face conveyors. In underground coal mines, this coupling provides an optimal startup as well as operational control of the armored face conveyor. Additionally, the high thermal capacity allows for multiple startups even when heavily laden.

TD constant-fill fluid drive coupling

The TD constant-fill fluid drive coupling is used in tractors to dampen torsional vibration and torque shocks in the drive chain. This increases the service life of all drive components. In event of overload, the torque limiting properties of the coupling prevent the engine from stalling. Thanks to the fluid drive coupling, simple and convenient operation of the tractor is possible.

type TVV fluid drive coupling

The type CPC fill-controlled fluid drive couplings are particularly suitable for heavy-duty use on armored face conveyors in the underground mining industry. The CPC series coupling is designed to start your armored face conveyor in a controlled manner, even under heavily loaded conditions. Thanks to the innovative XL wheel profile, the coupling transfers up to 60% more power in the same installation space. Power transmission of up to 1,600 kW is possible. The coupling provides very high thermal capacity, which allows for multiple startups.

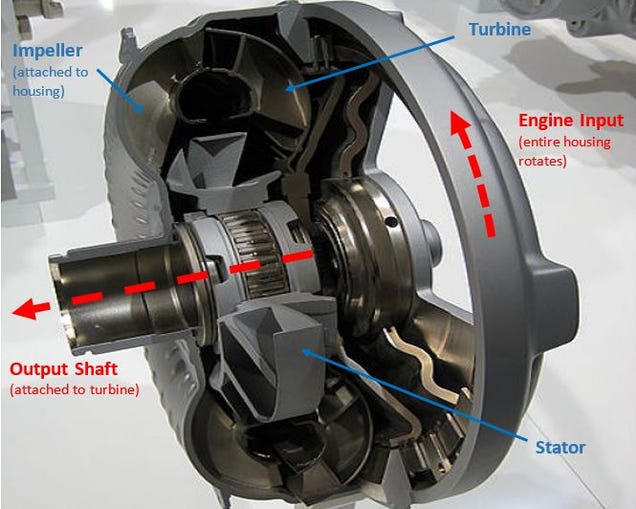

Fluid Drive Coupling Its Parts

An Introduction to the fluid drive coupling and Its Parts:

Fluid drive coupling, also known as the hydraulic coupling is a hydrodynamic device that is used to transfer rotational power from one shaft to another by the use of transmission fluid comprised of three main elements:

(1)Driving impeller mounted on the input shaft.

(2)Driven impeller mounted on the output shaft.

(3)Cover, flanged to the output impeller, with an oil-tight seal.

The Working Principle of Fluid Drive Coupling

The working principle of fluid drive coupling can be easily explained by the taking two fans in which one is connected to the power supply and other is not. When the power switch is on, the air from the first fan starts to blow towards the second fan (which is not connected to the power source). Initially, when the first fan is blowing at lower speed, it is not able to drive the second fan. But as the speed of the powered fan increases, the speed of air striking the blades of second fan also increases and it starts to rotate.

Fluid drive couplings or hydraulic couplings work on the hydrodynamic principle. In drives consisting fluid couplings, there is no mechanical contact between the driver and the driven machine and power is transmitted by means of a fluid. Due to the mechanical separation between the driver and the driven machine, a fluid drive coupling achieves two separate value of acceleration in the drive, the fast value of acceleration for the driver and simultaneously the slow value of acceleration for the driven machine.

Fluid drive couplings are often used to drive large inertia machines in combination with squirrel cage motors. They permit a load free acceleration of the motor and consequently with increasing oil fill, provide a soft/gentle quasi steady state start-up of the machine.

Fluid drive couplings are used in drives for conveyor systems such as belt conveyors, bucket elevators and chain conveyors. The smooth application of fluid coupling torque provides a smooth start-up of belt conveyor to protect the belt from damaging stresses.

In heavy industry, they are used for applications such as crushers, roller presses, mixers, large ventilators, boiler feed pumps, large compressors, centrifuges, etc.

How to Use a Fluid Drive Coupling?

(1) Industrial Applications

Fluid drive couplings are used in many industrial applications involving rotational power, especially in machine drives that involve high-inertia begins or continuous cyclic loading.

(2) Rail transportation

Fluid drive couplings are found in some Diesel locomotives as part of the power transmitting system. Self-Changing Gears made semi-automated transmissions for many counties’ Railways.

The role of fluid drive couplings

Fluid drive couplings are fixed fill mechanical soft start devices which utilize hydrokinetic energy to transmit torque through a system of impellers. The input impeller functions similar to a centrifugal pump and hydraulic turbine. When the input drive moves, it transmits kinetic energy to the oil which is distributed in the housing and transmits torque by engaging the outer impeller. The Fluid drive coupling allows the driver to start under “no load”, resulting in a smooth start up and reduction of amp draw from the motor. Since there is no physical connection inside the housing, the Fluid coupling has built-in overload protection and inherent torsional vibration absorption. Additionally, load balancing is possible with the use of asynchronous motors, instead of custom motors, since the Fluid drive couplings automatically adjust to load speed.

Important Questions

1. Why the output speed of a fluid drive coupling is always lower than the input speed?

Slip is an essential and inherent characteristic of a fluid drive coupling resulting in several advantages. To enable the fluid to flow from impeller to rotor, there must be a difference in ‘Head’ between the two, and thus there must be a difference in speed known as slip between the two. As the slip increases, more and more fluid can be transferred from the impeller to the rotor, and more torque is transmitted.

2. What is the importance of the type of operating fluid used in fluid drive coupling?

Characteristics of operating fluid affect the transmission behavior of a coupling. The higher the density of the operating fluid, the better the transmission capacity. The higher the viscosity of the working fluid, the more negative the transmission behavior. The viscosity Index and flashpoints of operating fluid are also important. It must be ensured that the operating fluid is compatible with coupling components and their materials and working conditions.

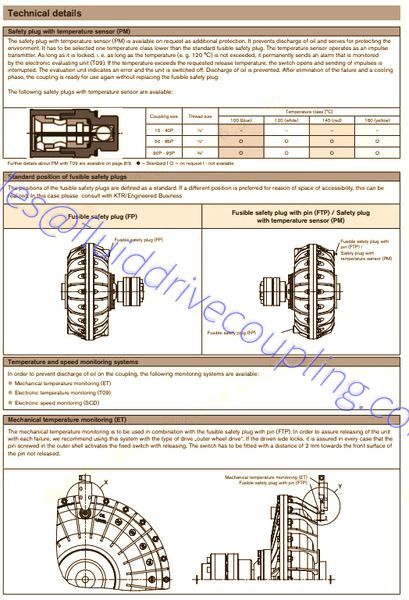

3. What is the purpose of Thermal Protection on constant fill fluid drive couplings?

Thermal protection on this type of coupling provides the fluid drive coupling safety and directly to the driver and driven machine. A fusible plug is the most common thermal protection. Suppose the fluid temperature in the coupling increases for any reason (which includes overloads). In that case, the fusible metal in the plug melts & all the liquid in the collar drains out, thus stopping power transmission and overloading the prime mover.

4. What kind of oil does a fluid drive coupling need?

Typically, mineral oil of viscosity class ISO VG 32 is used for constant fill type coupling and ISO VG 46 for variable speed coupling.

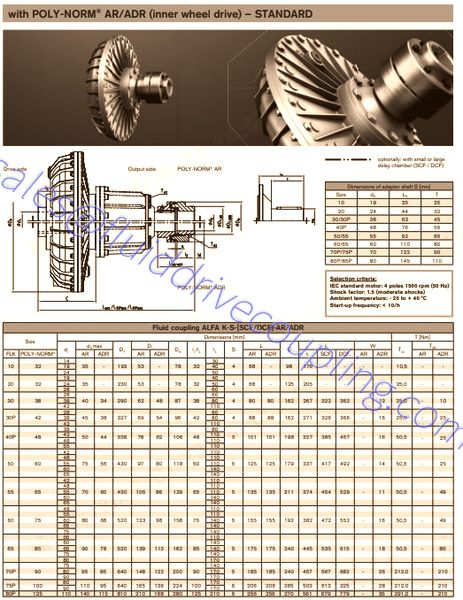

Technical Details

Contact Us Anytime!

Fluid drive coupling has many application in industrial machines and locomotives. They are used in mining, textile industries, oil and gas industries and other material handling industries. Fluid drive coupling can be used in very extreme condition like high engine vibration. The fluid utilized in the coupling can successfully absorb such vibration, so they are best for cyclic loading conditions. The fluid drive coupling can also act as a hydrodynamic break.If you are interested in our products, please send us an email!