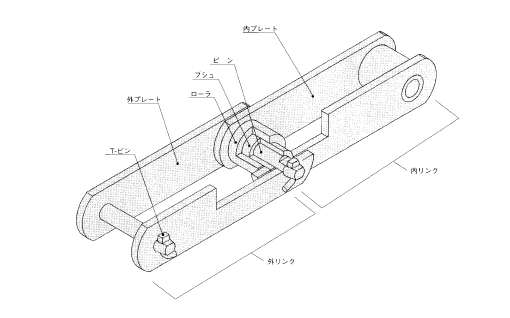

A DK conveyor chain includes a framework, and the names of the components are stated during the drawing. These elements have functions specified under.

Pins

Pins assistance all of the load acting over the chain together with plates, and when the chain is engaged together with the sprockets, they slide together with bushings as bearings. They’re subject to dress in and especially have to have large shear strength, bending strength and put on resistance. Hardened and tempered tough steel, carburized steel, or induction-hardened steel is utilised.

Rollers

Rollers protect the chain from shocks with all the sprockets, and once the chain is engaged using the sprockets, the rollers bend the chain smoothly and act to reduce the resistance when the chain runs on a rail. They may be required to possess high shock fatigue strength, collapse strength and put on resistance. Hardened and tempered hard steel, carburized steel or induction-hardened steel is made use of.

Bushings

Bushings are situated among pins and rollers and act as bearings for each the pins and rollers to not transmit the load received through the rollers immediately for the pins when the chain is engaged using the sprockets. These are demanded to possess higher shock fatigue strength, collapse strength and wear resistance, and generally, carburized

Plates

Plates are subject to repeated tension on the chain and sometimes to large shocks. They may be required to have high tensile power, and especially large shock power and fatigue strength. High tensile steel is employed for regular chains and heat-treated alloy steel for heavy-duty chains.

T-pins

T-pins prevent the outer plates from disengaging in the pins. They can be made of soft steel because pins are frequently pressed-in the outer plates and so no massive force acts to the T-pins.

Development and Elements of DK Conveyor Chains

Company Video

1. Installation & adjustment

After the equipment are arrived at the customer’s site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians’ guidance. Costs of the staff are decided at last.

2. Training

1) We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users’technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2) The buyer can send staff to our company for learning.

3. Quality assurance

1) We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2) We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3) We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4) The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer’s factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.