The following is usually a sample application utilised to illustrate the typical system for deciding on a Disc coupling. Any resemblance to any present company?¡¥s application is neither intentional nor meant to resemble that company?¡¥s actual application.

Sample Application:

An organization includes a compressor application working with a 225 horsepower electrical motor operating at 1,150 RPM to drive

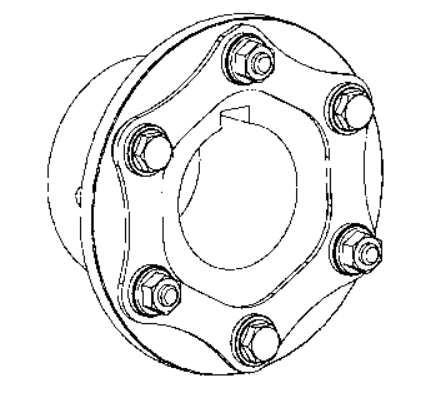

Phase 1: The very first phase is always to establish what coupling sort should be to be chosen for this application. Since the SU Style coupling only supports

just one flex plane, it may only accommodate angular and axial misalignment, but not parallel misalignment. The subsequent decision will be to search at an SX or DI Style coupling. The six bolt SX Variety will accommodate both parallel misalignment and also the defined shaft separation. The dimension will be determined through the selection torque plus the shaft diameters.

Step two: Upcoming, determine the application torque and apply the services element to determine the variety torque.The formula used to determine torque is as follows:

Application Torque ( in¡§Clb ) = ( HP x 63025 )/RPM

or Nm = ( KW x 9550)/RPM

Plugging in the numbers from the application description:

Application Torque ( in-lbs ) =(HP x 63025)/RPM = (225 x 63025)/1150 = 12,331 in-lbs

Application Torque x Service Issue = Variety Torque

12,331 in-lbs x 3.0 = 36,993 in-lbs

Step three: Make use of the SX coupling tables and note the SX 202-6 is rated at 40,700 in-lbs, in excess of ample to deal with the variety torque calculated in step two. The SX202-6, on the other hand, is not going to help the 92mm shaft dimension. The following bigger dimension coupling, the SX228-6, will support the 92mm shaft dimension as well as the shaft separation dimension (BSE) is six.88 inches, incredibly near to the application?¡¥s wanted 7 inch separation. The SX228-6 is rated at 62,000 in-lbs which may well seem to be excessive, having said that, the coupling dimension is necessary to take care of the bore dimension.

Step 4: The SX228-6 coupling is rated for any greatest unbalanced pace of 3,400 RPM, in excess of sufficient to assistance the application velocity of 1,150 RPM.

Phase five: To find out if the coupling will take care of the parallel misalignment, utilize the trig perform of tan 1?? = offset allowed for 1 inch = 0.0174

Multiply the 0.0174 x the distance among disc packs or ??S?¡¥ dimension through the table on web page D-13, or 5.50 inches.

The allowable parallel offset is 0.0174 x 5.50 = 0.096 inches. The utmost offset to the application is 1/32 inches (0.031), hence this coupling can accommodate the parallel misalignment.

Note: It really is often advisable to endeavor to set up the coupling at roughly 20% on the allowable misalignment. For this coupling the installer should really attempt to realize greater than 0.020 parallel misalignment in the time of set up. This will allow for the extra misalignment that should arise since the end result of products settle and basic equipment wear.

Methods In Deciding on A Disc Coupling

Company Video

1. Installation & adjustment

After the equipment are arrived at the customer’s site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians’ guidance. Costs of the staff are decided at last.

2. Training

1) We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users’technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2) The buyer can send staff to our company for learning.

3. Quality assurance

1) We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2) We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3) We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4) The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer’s factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.