Product Description

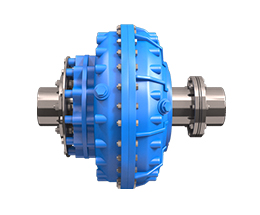

Flexible Tyre Coupling (ISO Certificated)

Product Name: type tire coupling

Surface treatment: phosphating, blackening and spraying

Coupling type: tire coupling

Material: Rubber

Scope of application: metallurgy, steel rolling, mining, chemical industry, shipbuilding, pumps, fans, etc.

Features: the tire coupling has good shock absorption and buffering effect and the performance of compensating the deviation between axles. It is widely used in the occasions of impact vibration, variable CHINAMFG and reverse rotation and frequent starting

1.High elastic material, silent work.

The ability of compensating relative displacement of 2 shafts is large, and the transmission torque is 10-2500n. M

2.Selected 45 steel, reliable quality.

The coupling theme is made of high quality 45 # steel

3.Deburring and smooth surface.

4.Complete models, a large number of stock, complete specifications.

Support non-standard customization. Please contact customer service. Various styles and complete types. Welcome to order!

5.Good damping. No lubrication, working temperature is 20-80 ºC

Related Products

Company Information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do fluid drive couplings contribute to reducing shocks and vibrations in mechanical systems?

Fluid drive couplings play a significant role in reducing shocks and vibrations in mechanical systems by absorbing and dampening undesirable dynamic forces. The unique design and operating principle of fluid drive couplings allow them to mitigate the impact of sudden changes in load or operating conditions.

Here are the ways in which fluid drive couplings contribute to shock and vibration reduction:

- Torque Dampening: Fluid drive couplings act as torque dampeners, reducing the rapid transmission of torque fluctuations from the driving to the driven element. When there is a sudden change in the torque demand, the hydraulic fluid in the coupling absorbs and dissipates the excess energy, preventing sudden jerks and shocks from propagating through the system.

- Flexible Coupling: Fluid drive couplings provide flexibility in the power transmission system. This flexibility allows the coupling to absorb misalignments and compensate for small angular or axial deviations between the driving and driven shafts. As a result, vibrations caused by misalignment are minimized, leading to smoother operation.

- Resonance Damping: Fluid drive couplings can help dampen vibrations caused by resonance in mechanical systems. Resonance occurs when the system’s natural frequency matches the excitation frequency, leading to excessive vibrations. The damping effect of the hydraulic fluid helps reduce the amplitude of the vibrations, preventing potential damage to the system.

- Overload Protection: In scenarios of sudden overloads or shock loads, fluid drive couplings can slip to protect the connected machinery from excessive stresses. This slip feature acts as a safety mechanism, preventing damage to the equipment and reducing the impact of the shock load on the system.

- No Metal-to-Metal Contact: Unlike some mechanical couplings, fluid drive couplings have no metal-to-metal contact between the driving and driven elements. The hydraulic fluid acts as a lubricant and cushion, reducing friction and wear, which can generate vibrations and noise in mechanical systems.

- Viscous Damping: The hydraulic fluid in the coupling provides viscous damping, dissipating energy as heat when the coupling experiences vibrations. This viscous damping effect helps reduce the amplitude and duration of mechanical vibrations.

By minimizing shocks and vibrations, fluid drive couplings improve the overall performance and reliability of mechanical systems. The reduction in dynamic forces helps decrease wear and tear on system components, extending their service life and reducing maintenance requirements.

It is essential to select the appropriate fluid drive coupling based on the specific application’s requirements to ensure optimal shock and vibration reduction. Regular maintenance and monitoring of the coupling’s condition also help maintain its effectiveness in dampening shocks and vibrations over time.

Can Fluid Drive Couplings Be Retrofitted Into Existing Systems to Improve Performance?

Yes, fluid drive couplings can be retrofitted into existing systems to improve performance and achieve various benefits. Fluid drive couplings, also known as hydraulic couplings, hydrodynamic couplings, or fluid couplings, are highly versatile and can be used in a wide range of applications.

Retrofitting a fluid drive coupling into an existing system offers several advantages:

- Reduced Shock Loads: Fluid drive couplings have the ability to cushion shock loads and dampen torsional vibrations. By retrofitting a fluid coupling, the system can experience smoother starts and stops, reducing stress on the connected equipment and improving overall system reliability.

- Overload Protection: Fluid couplings act as torque limiters, providing protection against sudden torque spikes and overloads. This helps safeguard sensitive machinery and prevents damage to the system during unexpected events.

- Energy Savings: Fluid drive couplings allow for gradual engagement, which reduces power peaks during starting and stopping operations. This leads to energy savings, especially in applications where frequent starts and stops are required.

- Flexible Power Transmission: Fluid couplings can accommodate slight misalignments between the driving and driven shafts, making them suitable for retrofitting into systems with existing misalignment issues.

- Increased System Lifespan: By reducing mechanical stresses and wear on the connected equipment, fluid drive couplings can extend the overall lifespan of the system, leading to lower maintenance costs and increased productivity.

- Smooth and Quiet Operation: Fluid drive couplings provide smooth and quiet power transmission, reducing noise levels and enhancing the comfort of operators and personnel working near the equipment.

When retrofitting a fluid drive coupling, it is essential to consider factors such as the specific application requirements, the torque and speed characteristics of the existing system, and the compatibility of the coupling with the connected equipment. Proper alignment and installation are also crucial to ensure optimal performance and longevity.

Overall, retrofitting fluid drive couplings into existing systems can be a cost-effective and beneficial solution to enhance performance, improve efficiency, and protect valuable machinery in various industrial applications.

What is a fluid drive coupling, and how does it function in mechanical power transmission?

A fluid drive coupling, also known as a hydraulic coupling, is a mechanical device used to transmit power between two shafts in a machinery system. It operates on the principle of hydrodynamic power transmission, utilizing hydraulic fluid to transfer torque and rotational motion from the driving shaft to the driven shaft.

The basic construction of a fluid drive coupling consists of two primary components: a driving impeller (pump) and a driven impeller (turbine), both housed within a sealed casing. The casing is filled with hydraulic fluid, typically oil. When the driving impeller is activated, it starts rotating, creating a flow of hydraulic fluid within the casing. This fluid movement generates a hydraulic force that drives the driven impeller to rotate at the same speed as the driving impeller.

The key features of how a fluid drive coupling functions in mechanical power transmission are as follows:

- No Mechanical Contact: Fluid drive couplings are non-contact power transmission devices. There is no direct mechanical connection between the driving and driven shafts. Instead, they rely on the hydraulic fluid to transfer power.

- Torque Amplification: Fluid drive couplings can provide torque amplification during startup or when the driven shaft experiences resistance. As the driving impeller starts rotating, the hydraulic fluid movement gradually accelerates the driven impeller, effectively increasing the torque applied to the driven shaft.

- Smooth Operation: Due to the hydrodynamic nature of power transmission, fluid drive couplings offer smooth and gradual acceleration, reducing shock loads on the machinery and minimizing wear on mechanical components.

- Slip Control: In certain applications, fluid drive couplings allow controlled slippage between the driving and driven shafts. This feature can protect the machinery from sudden overloads and act as a safety mechanism during transient operations.

- Speed Regulation: Fluid drive couplings can regulate the speed of the driven shaft by adjusting the input speed of the driving shaft. This speed regulation can be useful in applications where precise control of output speed is required.

- Overload Protection: In cases of excessive load or torque, fluid drive couplings can slip, absorbing the excess energy and protecting the machinery from damage.

Fluid drive couplings find applications in various industries, including automotive, industrial machinery, mining, and marine. They are commonly used in applications where smooth power transmission, torque amplification, and overload protection are crucial.

It’s essential to consider the specific requirements of the machinery system and the torque and speed characteristics when selecting a fluid drive coupling. Proper maintenance and monitoring of hydraulic fluid levels and condition are necessary to ensure optimal performance and longevity of the fluid drive coupling in mechanical power transmission.

editor by CX 2024-02-27