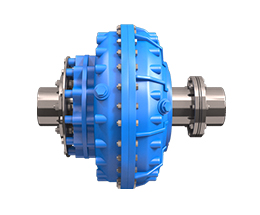

Product Description

219 5CF Excavator Part Coupling Rubber Coupling 5CF00001-UP 6W-1958 Of 6W3097

Basic information:

| Place of Origin | ZheJiang , China (Mainland) |

| Brand Name | Y&F |

| Model Number: | Centaflex, Miki pulley, Lovejoy coupling |

| .Material | High Temperature Rubber, Natural Rubber |

| Color | Black |

| Sales type | Retail, Wholesale |

| Mark | According to customer needs |

| Application | Construction machinery, ships, generators, compressors |

| Quality | Control strict 100% test |

| Mass production | Booking |

| Available | In stock |

| Model No. | 6W3097,219 5CF ,5CF00001-UP |

Product show as below:

Procucts information:

| Pos. | Part No | Qty | Parts name | Comments |

|---|---|---|---|---|

| 1. | 6A-6492 | [1] | COVER-FINAL DRIVE | |

| 2. | 5C-1834 | [1] | GEAR (13 TEETH) | |

| 3. | 8B-4967 | [1] | SEAL-O-RING | |

| 4. | 6A-6491 | [1] | HOUSING AS | |

| 5. | 1A-3284 | [2] | DOWEL | |

| 6. | 2H- 0571 | [1] | CONE-ROLLER BEARING | |

| 7. | 2H-0929 | [1] | CUP-ROLLER BEARING | |

| 8. | 5C-5937 | [1] | GEAR (53 TEETH) | |

| 9. | 9S-3581 | [2] | CUP-ROLLER BEARING | |

| 10. | 9S-3582 | [2] | CONE-ROLLER BEARING | |

| 11. | 5C-8583 | [1] | GEAR-RING (49 TEETH) | |

| 12. | 6C-3495 | [1] | SPROCKET AS | |

| 2H-1190 | [1] | PIN-DOWEL | ||

| 13. | 5P-2545 | [1] | SEAL-O-RING | |

| 14. | 5C-8587 | [1] | COVER | |

| 15. | 2P-1373 | [1] | CUP-ROLLER BEARING | |

| 16. | 9W-6645 | [1] | SEAL GP-DUO-CONE | |

| 5K-5129 | [2] | RING-SEALING | ||

| 17. | 6C-2828 | [1] | CAP | |

| 18. | 6C-571 | [1] | CARRIER AS | |

| 2D-0604 | [1] | BUTTON | ||

| 19. | 2K-571 | [1] | BOLT | |

| 20. | 7M-8485 | [1] | SEAL-O-RING | |

| 21. | 8T-4994 | [24] | WASHER | |

| 22. | 8V-4735 | [1] | RING-SEAL | |

| 23. | 1D-4608 | [8] | BOLT | |

| 24. | 5P-8248 | [8] | WASHER-HARD | |

| 25. | 4E-9426 | [1] | COLLAR | |

| 8C-8422 | SEALANT | |||

| 26. | 2K-2939 | [1] | SEAL-O-RING | |

| 27. | 2P-1374 | [1] | CONE-ROLLER BEARING | |

| 28. | 5C-8585 | [1] | RING-LOCK | |

| 29. | 5C-9120 | [6] | WASHER (STEEL) | |

| 5C-9119 | [6] | WASHER (BRONZE) | ||

| 30. | [12] | BOLT | ||

| 31. | 6A-7528 | [1] | SHIM-PACK (INCL 21 SHIMS) | |

| 32. | 5C-8584 | [3] | GEAR-PLANETARY (17 TEETH) | |

| 33. | 6V-4593 | [3] | BEARING AS-SPECIAL | |

| 34. | 8T-9399 | [12] | BOLT | |

| 35. | 5C-8582 | [3] | SHAFT-PLANETARY | |

| 36. | 9K-1171 | [1] | CUP-ROLLER BEARING | |

| 37. | 8D-2256 | [1] | CONE-ROLLER BEARING | |

| 38. | 5C-8967 | [1] | GEAR (52 TEETH) | |

| 39. | 5C-8586 | [1] | GEAR (74 TEETH) | |

| 40. | 6A-4498 | [1] | SHIM-PACK (INCL 21 SHIMS) | |

| 41. | 5P-2566 | [5] | BOLT | |

| 42. | 8T-4223 | [21] | WASHER | |

| 43. | 8S-9152 | [2] | CONE-ROLLER BEARING | |

| 44. | 6A-4497 | [1] | CAGE-BEARING | |

| 45. | 6A-7536 | [1] | PLUG AS | |

| 2D-0604 | [1] | BUTTON | ||

| 46. | 5M-7423 | [1] | SEAL-O-RING | |

| 47. | 8S-9151 | [2] | CUP-ROLLER BEARING | |

| 48. | 8F-9516 | [1] | SEAL-O-RING | |

| 49. | 6A-4495 | [1] | SHIM-PACK (INCL 21 SHIMS) | |

| 50. | 8T-2502 | [5] | BOLT | |

| 8T-4896 | [5] | WASHER-HARD | ||

| 51. | 6A-4493 | [1] | CAGE-BEARING | |

| 52. | 5C-8966 | [1] | GEAR (14 TEETH) | |

| 53. | 1H-7339 | [1] | SEAL-O-RING | |

| 54. | 3B-5790 | [1] | CUP-ROLLER BEARING | |

| 55. | 6V-2323 | [1] | CONE-ROLLER BEARING | |

| 56. | 5C-0862 | [1] | CAGE-BEARING | |

| 57. | 2H-4145 | [1] | SEAL-O-RING | |

| 58. | 6A-4492 | [1] | SHIM-PACK (INCL 21 SHIMS) | |

| 59. | 8T-8919 | [16] | BOLT | |

| 60. | 3B-571 | [2] | PLUG-PIPE | |

| 61. | 7D-9766 | [1] | BOLT | |

| 8K-8517 | [1] | WASHER | ||

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the different fluid media used in fluid drive couplings, such as oil or water?

Fluid drive couplings can use various types of hydraulic fluids as the medium to transmit torque between the driving and driven elements. The choice of fluid media depends on the specific application requirements and the operating conditions. Some common fluid media used in fluid drive couplings include:

- Oil: Mineral oil, synthetic oil, or a blend of various oils are commonly used as hydraulic fluids in fluid drive couplings. These oils offer good lubrication properties and thermal stability, making them suitable for various industrial applications. Oil-based fluid drive couplings are often preferred for heavy-duty and high-temperature applications.

- Water-Glycol: Water-glycol mixtures are widely used as hydraulic fluids in fluid drive couplings that require fire-resistant properties. These fluids are commonly used in industries where fire hazards are a concern, such as steel mills and foundries.

- Water-Oil Emulsions: Emulsions of water and oil are used in certain fluid drive couplings, especially in applications where fire resistance and cooling properties are essential. Water-oil emulsions provide both good lubrication and effective heat dissipation capabilities.

- Water: In some specific applications, plain water is used as the hydraulic fluid in fluid drive couplings. Water offers excellent cooling properties and is suitable for applications where there is no risk of freezing or where fire resistance is not a primary concern.

- Biodegradable Fluids: Biodegradable hydraulic fluids, such as vegetable-based oils or synthetic esters, are employed in environmentally sensitive applications. These fluids are biodegradable and offer good lubrication properties while minimizing environmental impact.

- Specialty Fluids: Depending on the specific requirements of niche applications, other specialty hydraulic fluids with unique properties may be used in fluid drive couplings. These specialty fluids are tailored to meet specific demands, such as extreme temperatures or aggressive operating environments.

The selection of the appropriate hydraulic fluid for a fluid drive coupling depends on factors like the operating temperature, load conditions, environmental considerations, and compatibility with the coupling’s materials. Manufacturers usually provide guidelines on the suitable fluid types and specifications for their specific fluid drive coupling models.

Regular monitoring and maintenance of the hydraulic fluid are essential to ensure optimal performance and to extend the service life of the fluid drive coupling. Fluid condition monitoring helps identify any signs of contamination or degradation, enabling timely fluid replacement or treatment as necessary.

It is crucial to follow the manufacturer’s recommendations regarding fluid type, fluid level, and fluid change intervals to ensure the fluid drive coupling operates efficiently and reliably in its intended application.

Real-World Examples of Successful Fluid Drive Coupling Installations and Their Benefits

Fluid drive couplings, also known as hydraulic couplings or fluid couplings, have been widely used in various industrial applications to achieve numerous benefits. Here are some real-world examples of successful fluid drive coupling installations and the advantages they offer:

- Mining Industry:

In large mining operations, fluid drive couplings are commonly used in conveyor belt systems to control the starting and stopping of the belts. The fluid coupling provides smooth and gradual acceleration, reducing shock loads on the conveyor system and minimizing wear and tear on the belts and other components. This results in increased equipment lifespan and reduced maintenance costs. Additionally, the fluid coupling offers overload protection, preventing damage to the conveyor system in case of sudden overloads or blockages.

- Steel Industry:

In steel mills, fluid drive couplings are utilized in various applications, such as rolling mills and large fans. In rolling mills, fluid couplings help maintain a constant speed during rolling operations, ensuring consistent product quality. The fluid coupling’s ability to absorb shock loads and torsional vibrations protects the rolling mill equipment and reduces downtime. In cooling and ventilation fans, fluid couplings provide soft starts and smooth speed control, leading to energy savings and quieter operation.

- Power Generation:

In power plants, fluid drive couplings are commonly used in steam turbines and gas turbines. Fluid couplings allow for controlled acceleration of the turbines, reducing the mechanical stress on the blades and rotor during startup. This results in extended turbine life and improved reliability. Additionally, fluid couplings help improve grid stability by enabling gradual synchronization with the power grid during startup.

- Marine Industry:

In marine propulsion systems, fluid drive couplings are employed to connect diesel engines to propellers. The fluid coupling ensures smooth torque transmission and absorbs torsional vibrations, preventing damage to the propulsion system and increasing the lifespan of the engine and gearbox. Additionally, the fluid coupling offers overload protection, safeguarding the engine and drivetrain from sudden load changes.

- Pumping Applications:

In water and wastewater treatment plants, fluid drive couplings are commonly used in pump applications. The fluid coupling enables soft starts, reducing the impact on the pump and electrical system during startup. This results in energy savings and extended pump life. Additionally, the fluid coupling’s ability to dampen torsional vibrations minimizes wear on pump bearings and mechanical seals.

These real-world examples illustrate the versatility and effectiveness of fluid drive couplings in various industries. Whether in mining, steel production, power generation, marine propulsion, or pumping applications, fluid couplings provide reliable and efficient power transmission while offering benefits such as reduced maintenance, energy savings, increased equipment lifespan, and improved system reliability.

“`

What is a fluid drive coupling, and how does it function in mechanical power transmission?

A fluid drive coupling, also known as a hydraulic coupling, is a mechanical device used to transmit power between two shafts in a machinery system. It operates on the principle of hydrodynamic power transmission, utilizing hydraulic fluid to transfer torque and rotational motion from the driving shaft to the driven shaft.

The basic construction of a fluid drive coupling consists of two primary components: a driving impeller (pump) and a driven impeller (turbine), both housed within a sealed casing. The casing is filled with hydraulic fluid, typically oil. When the driving impeller is activated, it starts rotating, creating a flow of hydraulic fluid within the casing. This fluid movement generates a hydraulic force that drives the driven impeller to rotate at the same speed as the driving impeller.

The key features of how a fluid drive coupling functions in mechanical power transmission are as follows:

- No Mechanical Contact: Fluid drive couplings are non-contact power transmission devices. There is no direct mechanical connection between the driving and driven shafts. Instead, they rely on the hydraulic fluid to transfer power.

- Torque Amplification: Fluid drive couplings can provide torque amplification during startup or when the driven shaft experiences resistance. As the driving impeller starts rotating, the hydraulic fluid movement gradually accelerates the driven impeller, effectively increasing the torque applied to the driven shaft.

- Smooth Operation: Due to the hydrodynamic nature of power transmission, fluid drive couplings offer smooth and gradual acceleration, reducing shock loads on the machinery and minimizing wear on mechanical components.

- Slip Control: In certain applications, fluid drive couplings allow controlled slippage between the driving and driven shafts. This feature can protect the machinery from sudden overloads and act as a safety mechanism during transient operations.

- Speed Regulation: Fluid drive couplings can regulate the speed of the driven shaft by adjusting the input speed of the driving shaft. This speed regulation can be useful in applications where precise control of output speed is required.

- Overload Protection: In cases of excessive load or torque, fluid drive couplings can slip, absorbing the excess energy and protecting the machinery from damage.

Fluid drive couplings find applications in various industries, including automotive, industrial machinery, mining, and marine. They are commonly used in applications where smooth power transmission, torque amplification, and overload protection are crucial.

It’s essential to consider the specific requirements of the machinery system and the torque and speed characteristics when selecting a fluid drive coupling. Proper maintenance and monitoring of hydraulic fluid levels and condition are necessary to ensure optimal performance and longevity of the fluid drive coupling in mechanical power transmission.

editor by CX 2024-03-09