Product Description

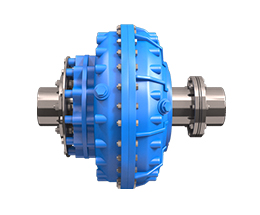

Excavator Coupling Type 80AS With Aluminium Block High Quality TXC225LC-2

Basic information:

| Marketing | Ordinary Product |

| Coupling Type | Coupling Inserts |

| Part Name | Excavator Coupling |

| Material | Pure Rubber |

| Outer Packing | Carton |

| Category | Construction machinery parts |

| Advantage | Flexible, Lower Noise |

| Condition | OEM New |

Why choose us:

Quality Controll

Competitive price

OEM Service

Experience more than 20 years’ experience

Wholesaler We supply a wide range of spare parts for excavators

Main products:

Seal Series:

arm cylinder seal kit, Boom cylinder seal kit, Bucket cylinder seal kit, main pump seal kit, travel motor seal kit,

swing motor seal kit, control valve seal kit, center joint seal kit, track adjust seal kit, bushings,

floating seals, o-ring box, pusher, etc.

Engine parts:

cylinder heads, cylinder blocks, crankshafts, camshafts, connecting rods, water pumps, turbo chargers,

engine assys, fan blades, main bearing and connecting rod bearings, pistons, piston rings, liner kits, etc.

Hydraulic parts:

hydraulic cylinder assembly, gear pump assembly, hydraulic pump assembly, travel motor assembly, final drive assembly, swing motor assembly,

main valve assembly, service valves, gasket kits, etc.

Electric Parts:

solenoid valves, water sensors, pressure sensors, throttle motors, stop solenoid, controllers, monitors, etc.

Other Parts:

seal kits, bushings, floating seals, o-ring box, pushers, couplings, engine cushions, bearings, gears, fuel filter

oil filter, air filter, track link assy, front idler, carrier roller, hydraulic oil cooler, water tank, track link assy, etc.

Product show as below:

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

FAQ

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can fluid drive couplings handle both angular and axial misalignments simultaneously?

Yes, fluid drive couplings are designed to handle both angular and axial misalignments simultaneously. The hydrodynamic principle used in fluid drive couplings allows them to accommodate misalignments between the driving and driven shafts in multiple directions.

Angular misalignment occurs when the axes of the driving and driven shafts are not perfectly parallel. Axial misalignment, on the other hand, refers to the misalignment of the two shafts along their common axis. In many real-world applications, both types of misalignment may exist.

Fluid drive couplings utilize a hydraulic fluid film to transmit torque between the impellers (pump and turbine) of the coupling. This fluid film creates a flexible and lubricating barrier between the impellers, enabling them to rotate independently of each other. As a result, the coupling can accommodate angular misalignment by allowing the impellers to tilt and follow the misaligned shafts’ angular positions.

Simultaneously, the fluid film also permits axial movement between the impellers, allowing the coupling to compensate for axial misalignment. When axial misalignment occurs, the fluid film cushions the impellers and permits axial displacement to occur without excessive stress or wear on the coupling.

The ability of fluid drive couplings to handle both angular and axial misalignments is one of their significant advantages over rigid mechanical couplings. Mechanical couplings, such as gear couplings or rigid couplings, are more sensitive to misalignments and may lead to premature wear, vibration, and increased stress on the connected machinery in case of misalignment.

However, it is essential to note that while fluid drive couplings can tolerate a certain degree of misalignment, excessive misalignment can still lead to reduced performance and increased wear over time. Regular monitoring of the coupling’s condition and addressing any significant misalignment issues is crucial to maintaining optimal performance and ensuring the longevity of the fluid drive coupling and the power transmission system it serves.

What are the standard sizes and specifications available for fluid drive couplings?

Fluid drive couplings come in a wide range of standard sizes and specifications to accommodate various mechanical power transmission applications. The sizes and specifications of fluid drive couplings are typically determined by the manufacturer and are based on industry standards and application requirements.

Some common standard sizes and specifications for fluid drive couplings include:

- Shaft Diameter: Fluid drive couplings are available in various shaft diameter options to fit different shaft sizes of the driving and driven elements. Standard shaft diameters range from a few millimeters to several inches.

- Power Rating: The power rating of fluid drive couplings indicates the maximum amount of power (torque and speed) the coupling can efficiently transmit. Power ratings can vary significantly based on the coupling’s size and design.

- Speed Range: Fluid drive couplings are designed to operate within specific speed ranges. Some couplings are optimized for high-speed applications, while others are suitable for low-speed or variable-speed applications.

- Torque Capacity: The torque capacity of a fluid drive coupling refers to the maximum amount of torque it can transmit without slipping. Torque capacity is an essential consideration for selecting a coupling that can handle the required load and torque demands of the application.

- Operating Temperature Range: Fluid drive couplings are designed to operate within specific temperature ranges. The operating temperature range depends on the type of hydraulic fluid used and the materials used in the coupling’s construction.

- Fluid Type: The type of hydraulic fluid used in the coupling can affect its performance and compatibility with the application. Various fluids, such as oils or water-based fluids, may be used depending on the specific requirements.

- Environmental Protection: Some fluid drive couplings may offer additional environmental protection features, such as sealing mechanisms or corrosion-resistant coatings, to ensure reliable operation in harsh or challenging environments.

It is essential to carefully consider the specific requirements of the application when selecting a fluid drive coupling. Factors such as the power demands, operating speed, torque requirements, environmental conditions, and space limitations should be taken into account to ensure the chosen coupling is suitable for the intended application.

Manufacturers of fluid drive couplings can provide detailed product catalogs and specifications that assist in selecting the appropriate coupling based on the system’s needs. Consulting with coupling experts and specifying the application’s parameters will help ensure the right fluid drive coupling is chosen for optimal performance and reliability in the mechanical power transmission system.

What is a fluid drive coupling, and how does it function in mechanical power transmission?

A fluid drive coupling, also known as a hydraulic coupling, is a mechanical device used to transmit power between two shafts in a machinery system. It operates on the principle of hydrodynamic power transmission, utilizing hydraulic fluid to transfer torque and rotational motion from the driving shaft to the driven shaft.

The basic construction of a fluid drive coupling consists of two primary components: a driving impeller (pump) and a driven impeller (turbine), both housed within a sealed casing. The casing is filled with hydraulic fluid, typically oil. When the driving impeller is activated, it starts rotating, creating a flow of hydraulic fluid within the casing. This fluid movement generates a hydraulic force that drives the driven impeller to rotate at the same speed as the driving impeller.

The key features of how a fluid drive coupling functions in mechanical power transmission are as follows:

- No Mechanical Contact: Fluid drive couplings are non-contact power transmission devices. There is no direct mechanical connection between the driving and driven shafts. Instead, they rely on the hydraulic fluid to transfer power.

- Torque Amplification: Fluid drive couplings can provide torque amplification during startup or when the driven shaft experiences resistance. As the driving impeller starts rotating, the hydraulic fluid movement gradually accelerates the driven impeller, effectively increasing the torque applied to the driven shaft.

- Smooth Operation: Due to the hydrodynamic nature of power transmission, fluid drive couplings offer smooth and gradual acceleration, reducing shock loads on the machinery and minimizing wear on mechanical components.

- Slip Control: In certain applications, fluid drive couplings allow controlled slippage between the driving and driven shafts. This feature can protect the machinery from sudden overloads and act as a safety mechanism during transient operations.

- Speed Regulation: Fluid drive couplings can regulate the speed of the driven shaft by adjusting the input speed of the driving shaft. This speed regulation can be useful in applications where precise control of output speed is required.

- Overload Protection: In cases of excessive load or torque, fluid drive couplings can slip, absorbing the excess energy and protecting the machinery from damage.

Fluid drive couplings find applications in various industries, including automotive, industrial machinery, mining, and marine. They are commonly used in applications where smooth power transmission, torque amplification, and overload protection are crucial.

It’s essential to consider the specific requirements of the machinery system and the torque and speed characteristics when selecting a fluid drive coupling. Proper maintenance and monitoring of hydraulic fluid levels and condition are necessary to ensure optimal performance and longevity of the fluid drive coupling in mechanical power transmission.

editor by CX 2024-02-24