Hydraulic flange fittings dimension is conform to SAE J518 and ISO 6162 4-bolt flange connection, fittings ends are designed with crimped-ferrule hose end, ISO 8434 series tube connector, socket weld and butt weld, Female port such as Metric, BSPP, UNF, NPT, BSPT port connections.

hydraulic flange fittings types asfollows:

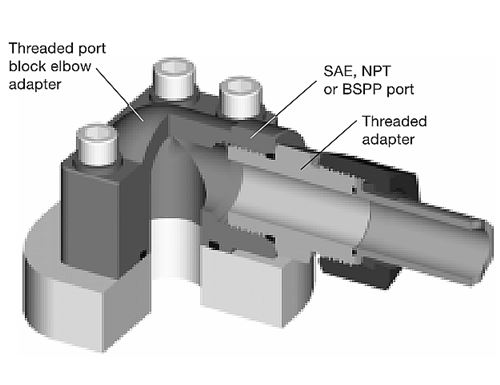

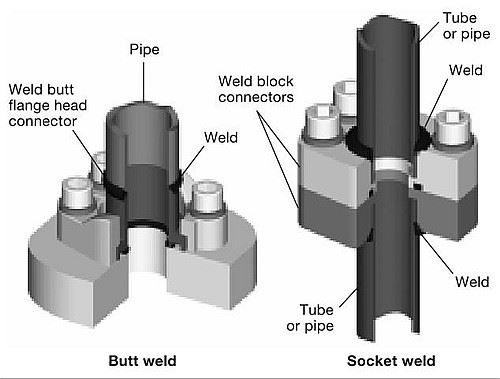

Hydraulic flange block fittings also called sae 4-bolt block flange fittings, it is designed with sae flange o ring groove dimensions, sae flange flat face port dimensions, flange block fittings end is designed with SAE ORB port, NPT port, BSPP port, socket weld and butt weld types.

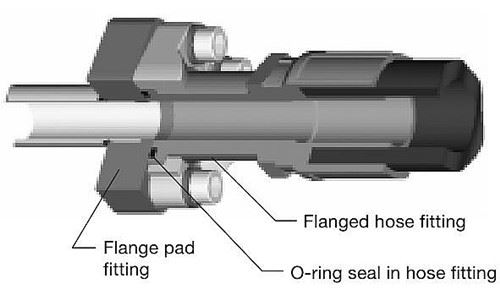

Hydraulic flange hose fittings also called sae flange head hose fittings, assemble with split flange halves.SAE flange head is designed with o-ring groove dimensions including 3000 psi and 6000 psi working pressure, hose end is designed with interlock 9000 psi, sprial hose 6000psi, wire hose 3000 psi. there are two piece sae hose flange and one piece hose flange fittings suit for various construction of hydraulic hoses.

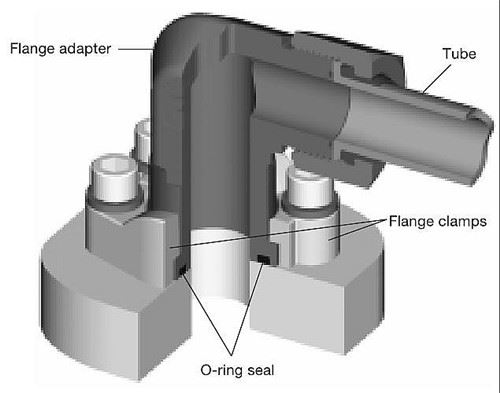

Hydraulic flange tube fittings also called sae flange adapters, assemble with sae flange clamps.SAE flange head is designed with o-ring groove dimensions. Flange tube fittings ends is available in straight thread port SAE ORB, metric, BSPP and UNF; taper thread port NPT, BSPT. shapes have straight, elbow, cross, tee etc.To connect hydraulic tubing, hydraulic piping, hydraulic hose assembly. working pressure type have code 62 flange adapters and code 61 flange adapters.

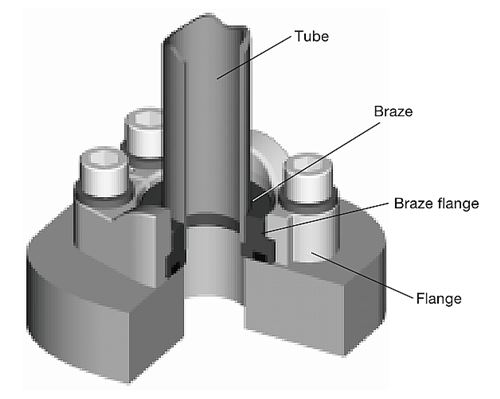

Hydraulic flange weld fittings also called sae weld flange fittings, welding tube connection permantly.SAE flange head is from ISO 6162 standard design, weld fittings ends are availble in socket weld, butt weld connections.it is assemble with SAE flange clamp by 4 bolts tightening.

Material types of hydraulic sae flange fittings and adapters:

Stainless steel hydraulic hose flange fittings

Carbon steel hydraulic sae flange adapters

Standards of hydraulic flange fittings

The 4-bolt flange connections conforming to SAE J518 and ISO 6162-1 and -2 are proven, leak-free connections, especially suited for larger sizes, higher pressures and assembly in tight quarters. Threaded port connections such as SAE straight thread O-ring and ISO 6149 are reasonably easy to assemble and provide 6000 psi and higher pressure capability up to size

12 (M27). Beyond this size the pressure rating starts to decrease and assembly torques increase rapidly. The 4-bolt flange port connections provide ability to connect larger sizes and achieve higher-pressure capability at reasonable assembly torques.

Videos of hydraulic flange fittings types introductions:

If you don't find what you need, please send email to [email protected]

Hot Tags: hydraulic flange fittings, China, manufacturers, suppliers, custom, brass, swagelok, Parker, Stauff, Brennan, stainless steel