SPROCKET Capabilities

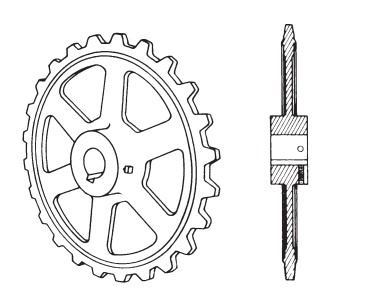

PLATE CENTER SPROCKETS

Sprockets are furnished in two simple sorts . . . Plate center and Spoked Arm. Plate centers are generally utilised on smaller sized sprockets whose dimension prohibits using spoked arms and on drives and conveyors that are subjected to frequent shock loads. These are also utilized when the maximum allowable chain pull is greater than that which Spoked Arm Sprockets

can stand up to.

SPOKED ARM SPROCKETS

Spoked arms are uncovered on big diameter sprockets. They are utilized to cut back bodyweight and facilitate handling.Lightening holes can also be utilized to cut back weight.

CHILLED RIM DISHED AND

FABRICATED DISHED

When creating cast prockets, we use a particular chemistry of gray iron that enhances the capability of your of the iron to form a tricky

Fabricated dished sprockets are produced to buy. Products and hard-ness are customized to your necessities.

CHAIN SAVER SPROCKETS

Chain Saver sprockets give added existence to chain due to the fact of the unique ?ange building on the rim. The chain side bars rest within the ?ange as chain wraps around the sprocket, retaining the chain to the accurate pitch line and distributing dress in over a better get in touch with place.

HUNTING TOOTH SPROCKETS

Hunting Tooth Sprockets last longer than ordinary sprockets and operate on this principle: Hunting Tooth Sprockets have an odd number of teeth and are half the pitch in the chain. Therefore, each time the sprocket can make a revolution, the chain links engage a brand new set of teeth, forward in the previously engaged set. Each and every tooth can make get hold of using the chain only half as several times as it would on the reg-ular sprocket, consequently doubling the existence of the sprocket.

SEGMENTAL RIM SPROCKETS

Segmental Rim Sprockets are designed to eliminate costly shut down time during set up and adjustment. They include a re-movable segmented rim and a strong or split entire body that are bolted together. To obtain extra dress in from this sort sprocket, just after con-siderable use, the rim sections may possibly be basically reversed, so that the chain can make get in touch with with the opposite sides of the teeth. Bodies or whole sprockets could be replaced without removing shaft or bear-ings, building this sort of sprocket really desirable economically be-cause on the cost savings in labor and shut-down time.

Wide FLANGE SPROCKETS

These Sprockets are utilized in several industries this kind of as the lumber and paper industries as sprockets for your delivery end of conveyors. The wide ?ange or side extension acts being a guard and assists maintain materials from getting wasted because it comes off the finish on the conveyor.

TRACTION WHEELS

Traction wheels can be found in a wide selection of sizes and sorts to ?t most chains. They are really furnished inside a plate-center type with op-tional lightening holes if necessary. Traction wheels is often either sound, split or segmented development.

SPROCKETS

Company Video

1. Installation & adjustment

After the equipment are arrived at the customer’s site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians’ guidance. Costs of the staff are decided at last.

2. Training

1) We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users’technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2) The buyer can send staff to our company for learning.

3. Quality assurance

1) We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2) We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3) We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4) The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer’s factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.