1. Definition of Test port couplings, because they are applied for the monitoring and control pressure as well as the ventilation. So we called test points. Test points can be found in power packs, valve blocks, hydraulic power units, hydraulic cylinders, heavy machinery and construction site machinery, earth moving machines, trucks, hydraulic test rigs, etc

2. The advantages of test point couplings are - among other - connection at system pressure level, the easy connection to measurement control and switching devices, the leak proof connection and the integrated vibration security of the metal cap. The application spectrum comprises

A) bleeding (e.g. draining pipes and other hydraulic components)

B) filling (e.g. refilling pipes and other hydraulic components with oil)

C) sampling (e.g. taking samples in a test tube for later chemical analysis)

D) pressure reading (e.g. for identification of pressure data).

3. Standards of Test point Adapters: As per BS ISO 15171-2-2016 Hydraulic couplings for diagnostic purposes diagnostic couplings with an M16x2 connection end that can be connected under pressure without tools to a maximum pressure of 10 MPa (400 bar) providing following stud ends:

ISO 6149-2 – M14 × 1,5;

ISO 9974-2 – M14 × 1,5;

ISO 1179-2 – G 1/4;

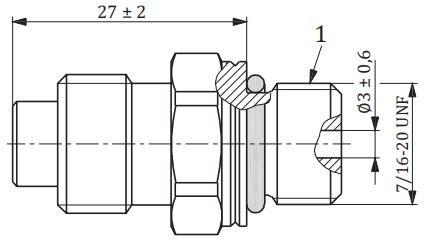

ISO 11926-2 – 7/16-20 UNF.

M16×2 threads conform to ISO 724, tolerance grade 6g for external and 6H for internal thread in accordance with ISO 965-1.

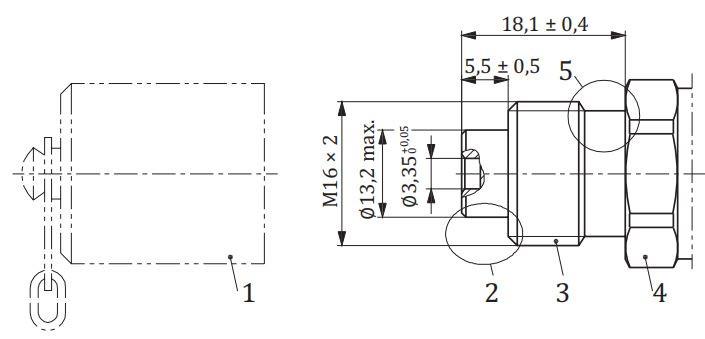

4. Method of test point end: 1 is the design cap at the discretion of the manufacturer, 2 is the design at the discretion of the manufacturer, 3 is diagnostic connection, 4 is optional design, 5 is vibration lock at the discretion of the manufacturer.

5. Diagnostic coupling with different port sealing:

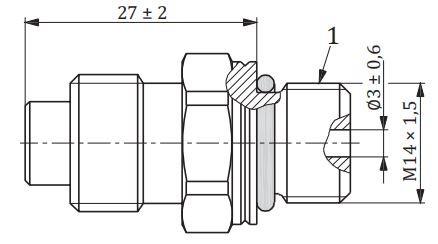

Diagnostic coupling with a stud end FM 14x1,5 in accordance with ISO 6149-2 O-ring seal

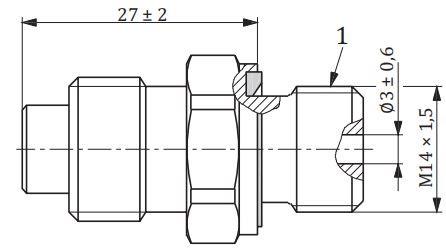

Diagnostic coupling with a stud end EM 14x1,5 in accordance with ISO 9974-2 Elastomeric seal

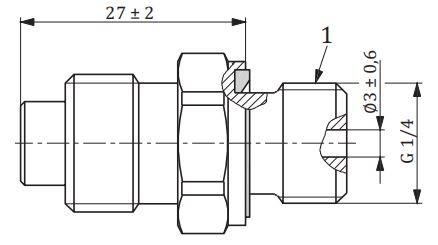

Diagnostic coupling with a stud end ISO 1179–2, G1/4 Elastomeric seal

Diagnostic coupling with a stud end ISO 11926–2–7/16-20 UNF O-ring seal

6. Materials: Metal parts: Steel, Stainless steel upon request as 316L, 304 etc. Seals:NBR (-20 °C to +100 °C); FKM (-20 °C to +200 °C);EPDM (-40 °C to +150 °C).Hose: Polyamide (-35 °C to +100 °C)

7. Finish is Zinc nickel, transparent, CrVI free.

Hot Tags: hydraulic test point fittings, China, manufacturers, suppliers, custom, brass, swagelok, Parker, Stauff, Brennan, stainless steel