Definition of Split Flange Kit, split flange is as per SAE J518 defined the four blot split flange half, also be equal to BS ISO 6162-1/2:2012 version; one kit is including 4 blots, 4 washers, o-ring and pair of 2-bolt split flange halves (clamps). they are used in conjunction with either flanged hose ends or with flanged adapters.

1. Definition of Split Flange Kit, split flange is as per SAE J518 defined the four blot split flange half, also be equal to BS ISO 6162-1/2:2012 version; one kit is including 4 blots, 4 washers, o-ring and pair of 2-bolt split flange halves (clamps). they are used in conjunction with either flanged hose ends or with flanged adapters.

2. Two series of working pressure as below:

● SAE J618 code 61 and ISO 6162-1 define the Flange connectors, ports and mounting surfaces for use at pressures of 3,5 MPa (35 bar) to 35 MPa (350 bar), DN 13 to DN 127.

● SAE J618 code 62 and ISO 6162-2 define the Flange connectors, ports and mounting surfaces for use at a pressure of 42 MPa (420 bar), DN 13 to DN 76.

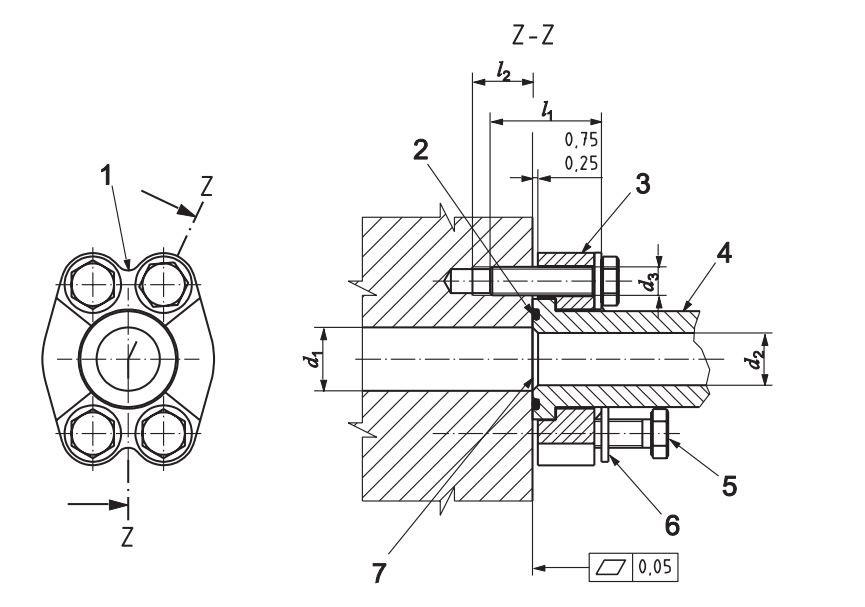

3. Method of SAE Split Flange assembly, it is the 4-blots port connection by assembling the flanged heads, split flange clamps (FCS and FCSM) or one-piece flange clamps (FC and FCM), ports and mounting surfaces applicable to four screw, split and one-piece flange clamp type tube connectors and hose fittings.

1) shape optional 2) O-ring seal 3) one-piece flange clamp 4) flanged head 5) blot screw (d3) 6) hardened washer 7) face of port on adapter, pump, etc

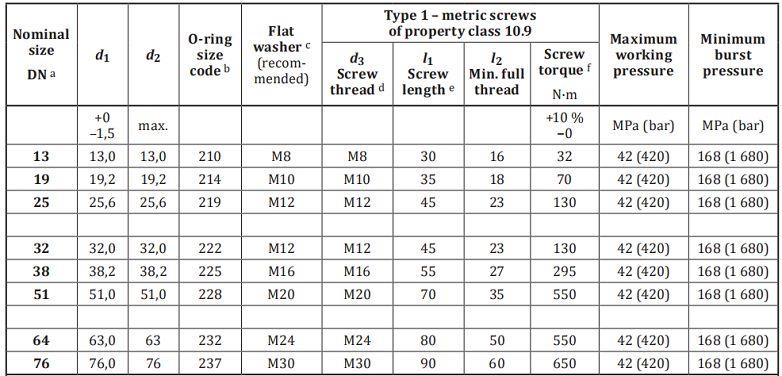

4. Metric blot screw for one-piece flange assembly technology information:

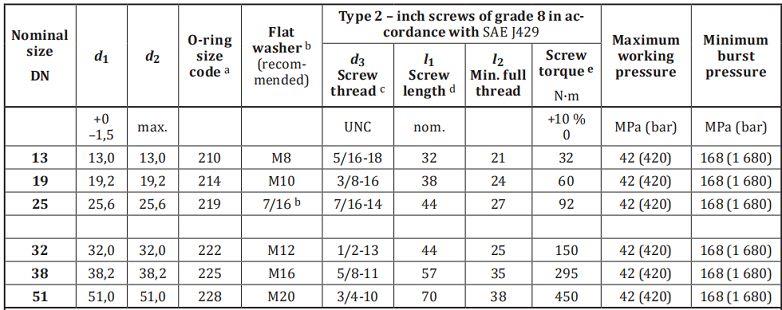

Inch blot screw for split flange assembly technology information

● Metric Coarse pitch thread in accordance with ISO 261 and ISO 724. Inch Coarse pitch thread in accordance with ISO 263 and ISO 725 (UNC-2A for screw threads, UNC-2B for port threads).

● Screw lengths are calculated for steel; use of other materials can require different screw lengths.

● These torque values are only a guide when using lubricated screws, calculated with a coefficient of friction of 0,17. Net tightening torque depends on many factors, including lubrication, coating and surface finish.

5. Harden washer s for assembling flange connections that conform to ISO 6162

The use of hardened washers is recommended; however, flange connections conforming to previous editions of ISO 6162-2 might not accommodate the use of this type of washer. Washers, if used, shall conform to ISO 7089 (HV 300) type A and be sized for the corresponding screw. Plain washers conforming to ANSI/ASME B18.22.1, type B narrow series HV 300, may be substituted when using type 2 screws

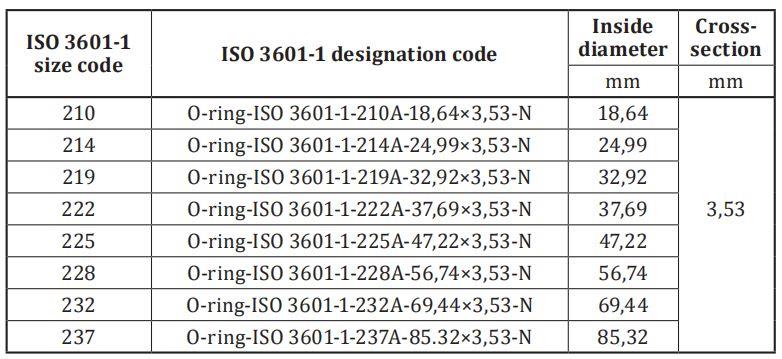

6. O-ring designation codes and dimensions that conform to ISO 3601-1

Designation codes and dimensions of O-rings used in ISO 6162-2 (for reference only)

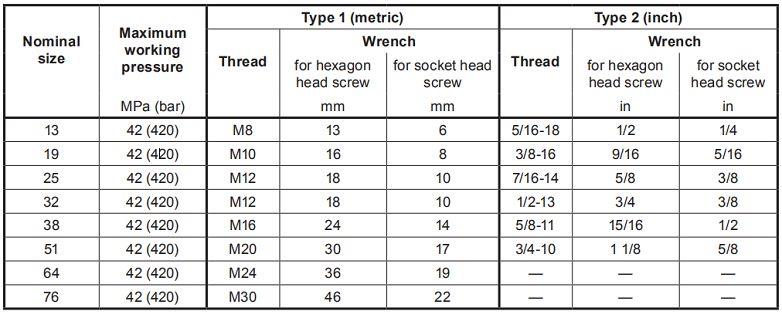

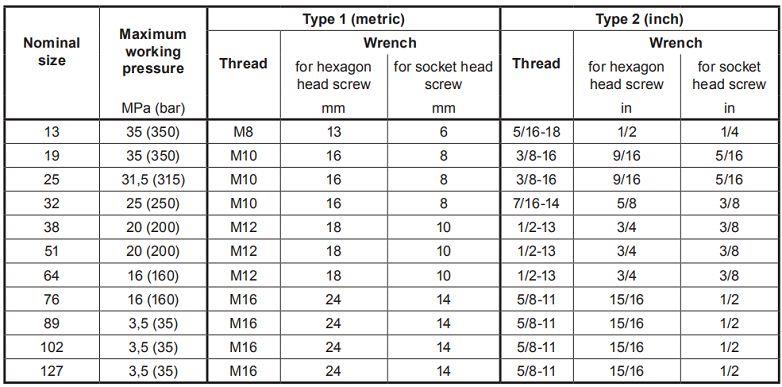

7. Wrench sizes for assembling flange connections that conform to ISO 6162

ISO 6162-1

ISO 6162-2